Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-373-2615111

Model No.: SDSF

Brand: Shengda

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Printing Shops, Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Not Available

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Gear

Place Of Origin: China

Filter Rating: 3-50micron: Structure:Inner pouched core,pleated filter layer and outer pouched support guard

Packaging: carton,plywood box

Productivity: 120000 pcs/ year

Transportation: Ocean,Land,Air,Express

Place of Origin: Xinxiang, Henan, China

Supply Ability: 10000pcs/ months

Certificate: ISO9001:2015

HS Code: 8421999090

Port: Qingdao,Shanghai,Tianjin

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,EXW,CIF,DDU,DDP,CIP,FCA,Express Delivery

Overview

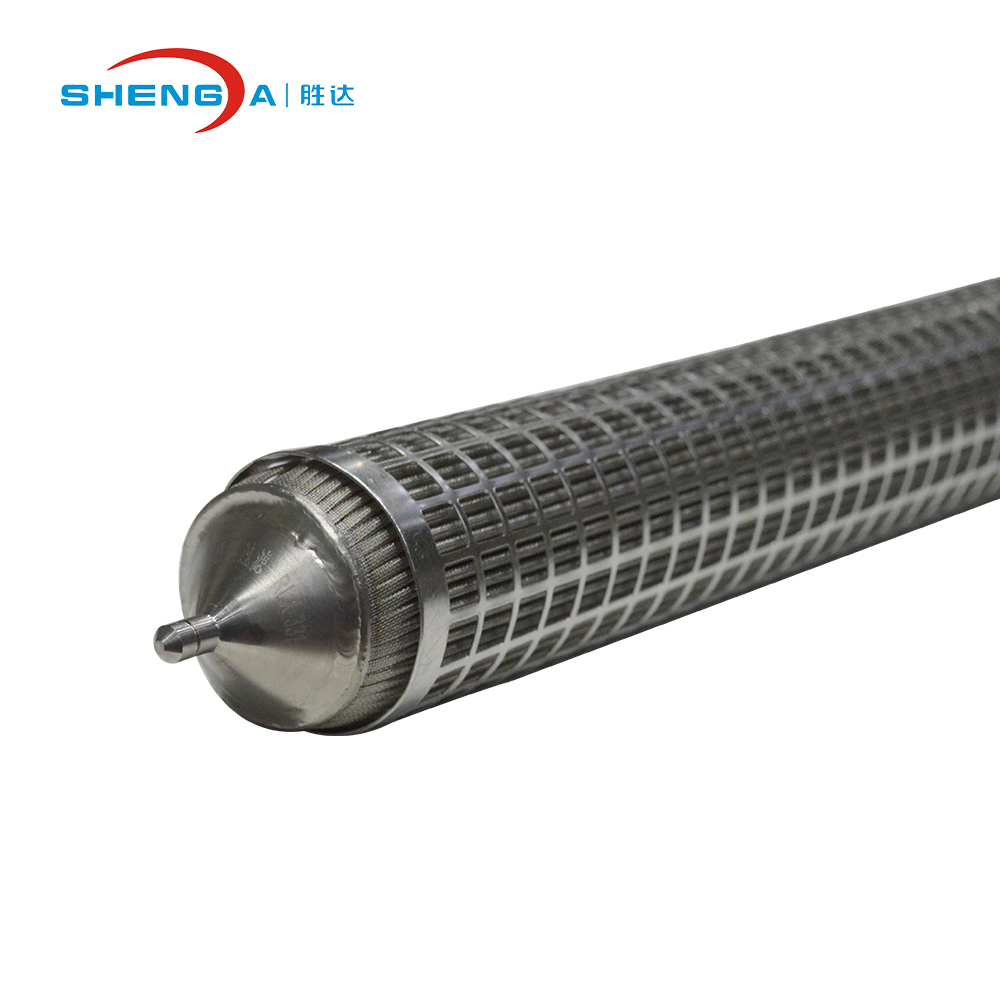

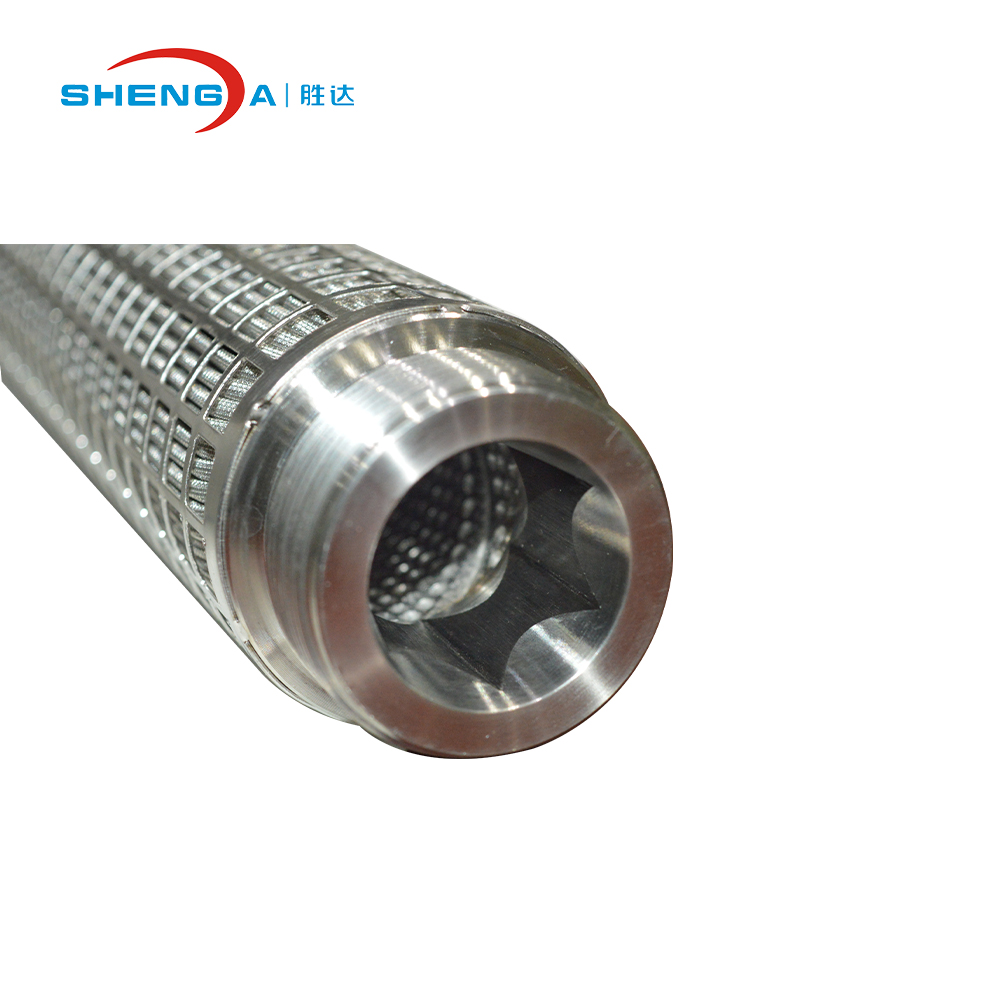

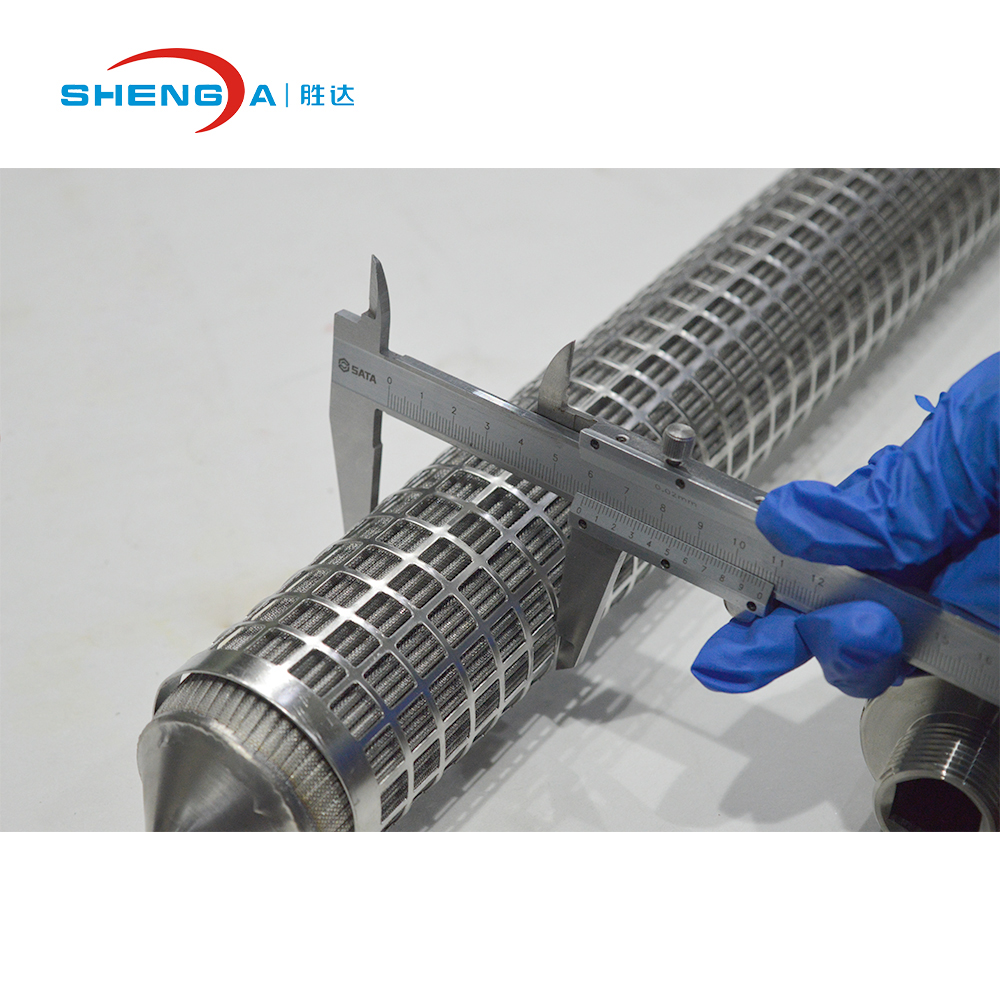

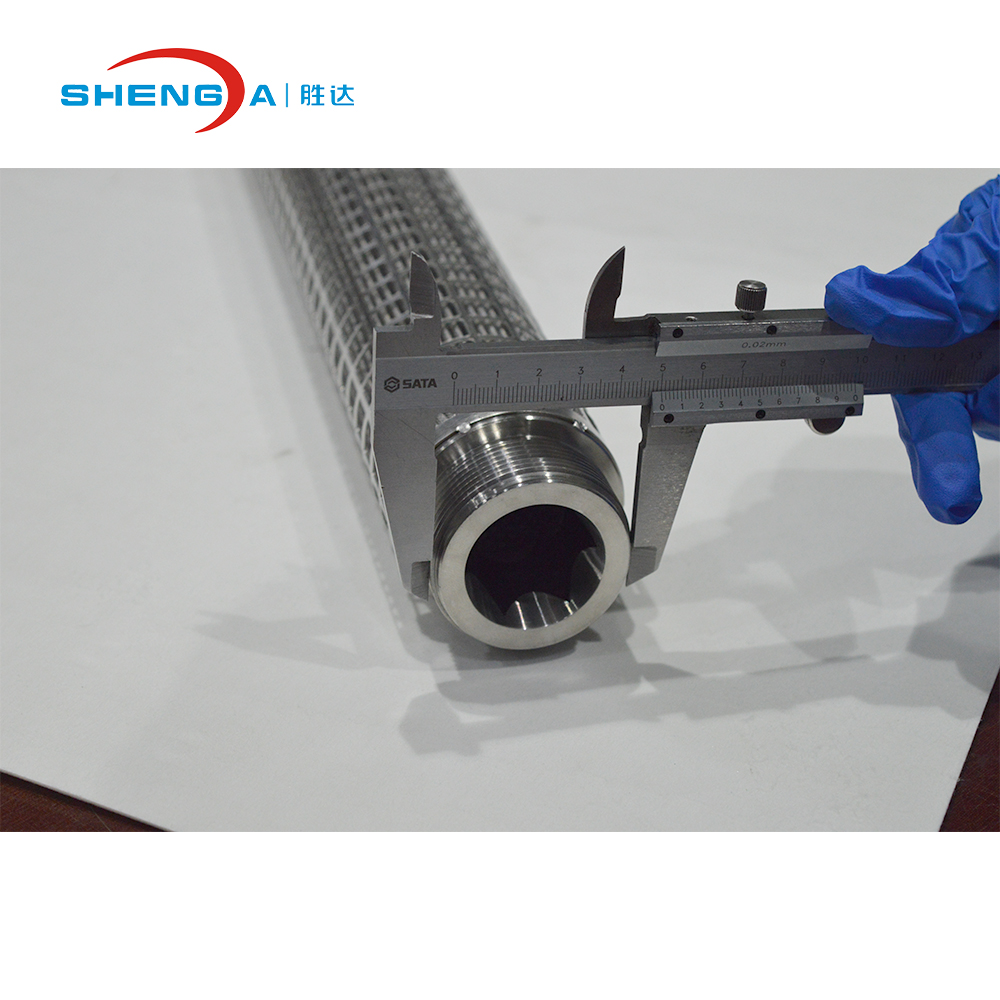

Sintered metal pleat candle filter manufactured from radomly laid metal fibres and sintered to form a uniform high porosity filter medium. The Pleated structure provides higher filtration area per candle filter, increases the dirt-holding capacity. The inner support core is made of high-strength spiral punched cores, the outer protective guard made of square punched cores (optional as per the customer’s need), and the lower end cover, designed as a guide cone, which design can effectively reduce resistance. Filter precision ranges between 3μm~100μm.

Product Categories : Filter Element > Melt Filter Element

Xinxiang Shengda Filtration Technique Co., Ltd, is engaged in designing and manufacturing filtration products and filter elements since 1998. Many professional engineers, experts devote to filtration & purification research and applications to offer technical support for the product designing and manufacturing.

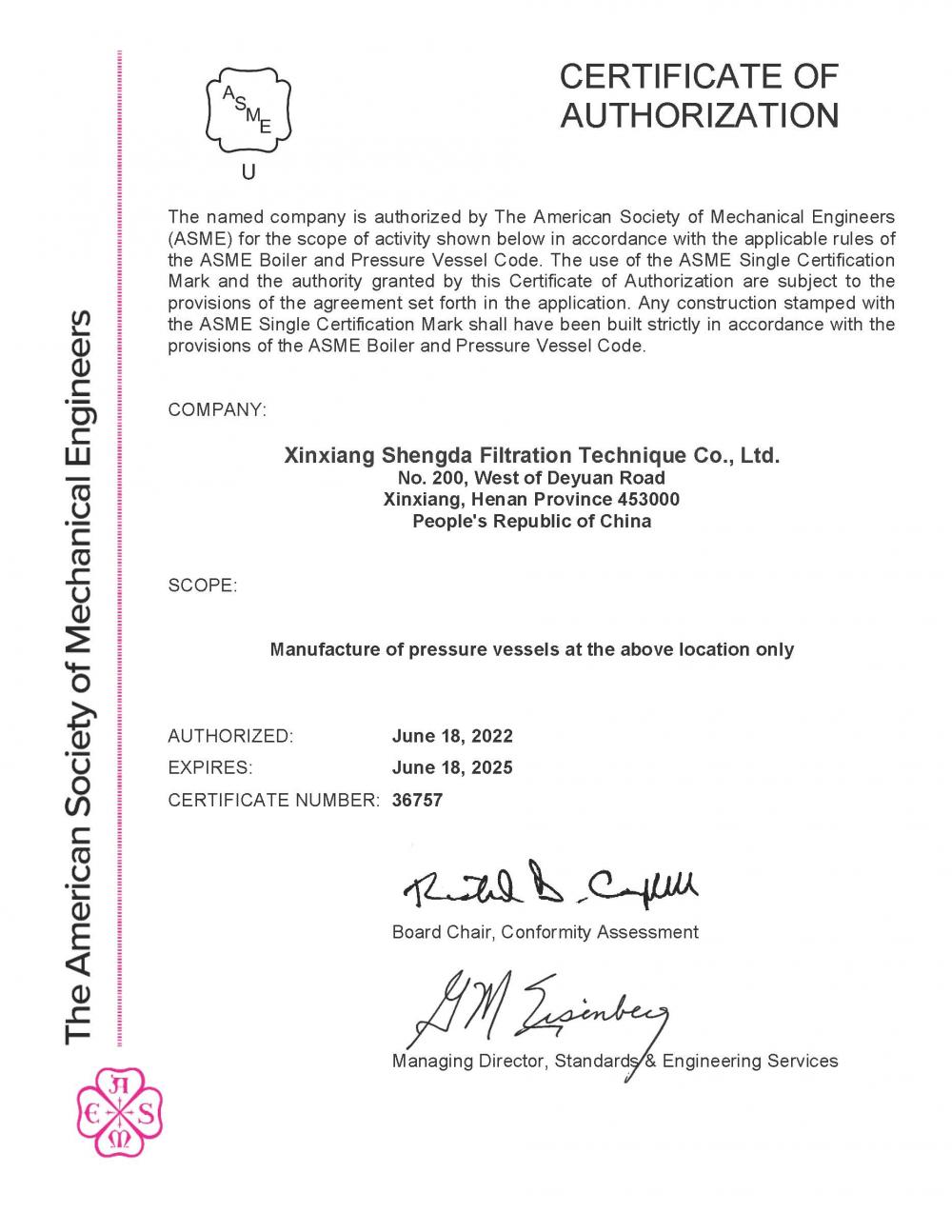

We have advanced manufacturing equipments, sophisticated production technology, perfect quality assurance system, we have passed the ISO 9001:2008 quality management system, ISO 14001:2004 Environmental Management System, OHSMS18001:2007 Occupational Health and Safety Management System, E/J9001-2014 Nuclear Industry Quality Management System, Design and Manufacture License of Category A1, A2, Design and Manufacture certificate of authorization and Regulation Stamping by the American Society of Mechanical Engineers (ASME)with U stamp.

Shengda Filtration filter media division has been devoted to researching, designing, testing and manufacturing metal fiber sintered felt (stainless steel, nickel, Hastelloy, Inconel, iron-chromium alloy), disc filter elements,multi-layer metal sintered mesh filter elements,metal powder sintered filter element. With 25 years of technical experience, process flexibility and material testing capabilities, we can provide products that meet customers' quality and performance requirements.

The products are mainly applied for chemical fiber, high molecule polymer,films,wind power, photovoltaics, hydropower, nuclear power, petroleum, gas turbine generation, engineering machinery, etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.